This website is useable but presently UNDER CONSTRUCTION FOR IMPROVEMENTS

WE'RE OPEN AND READY TO SERVE YOU!

Professional Shot Peening Services In The United States

Shot Peen:

A solution to increase the longevity of Manufacture Parts

A mechanical process commonly used to Improve surface residual stresses that occur during part manufacturing or during part operation.

Our services

Aviation Services

Transportation Services

Industrial Services

Areas We Serve

Hawaii

Erie

Maine

Pennsylvania

Michigan

South Carolina

Ohio

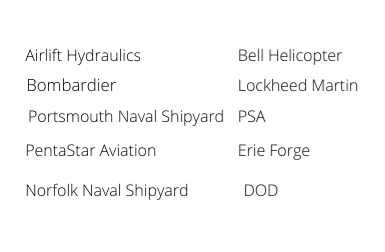

2000+

Clients Served

10K+

Contracts Completed

99%

Success Rate

Why Is It Used?

The main advantage of shot peening is to extend the service life of a component by creating an induced compressive stress layer to increase resistance to fatigue (including corrosion fatigue, stress corrosion and cavitation erosion) while also helping to resist the development and propagation of cracks.The creation of compression stresses that resist metal fatigue help prevent the propagation of cracks through the material. Stress corrosion cracking is also mitigated internally as the plastic deformation caused by the various types of shot peening and laser peening aids tensile stressed parts from the inside. However, tensile stresses inside a material are not as problematic, as surface cracks are less likely to start on the inside of a material.

Emergency service

Available 24X7 -Premium cost!

Our team is always ready to provide you with exceptional services at any point in time.

For emergency service call (724)-385-0536

Why choose us?

Available 24x7

Affordable Pricing

Licensed & Trusted

Locally Owned & Operated

What is Shot Peening?

Shot peening is the bombardment of the metal with small spherical tiny balls (known as media).

These tiny spherical balls are propelled out of a nozzle at predetermined distance and velocity to create a dent (like on a golf ball) at a prescribed intensity.

These dents create plasticity (plastic) zone up to 0.015 in depth. This plastic zone creates a 2nd yield point for a failure to overcome. By creating this second yield point helps to increase the longevity of manufacture parts of up to 1000 times (even more), then manufactured life.

Shot peen is often confused with abrasive shot blasting. Similar, BUT DIFFERENT. One is controlled and the other is not. Abrasive blasting is used for descaling and Rust removal. Where shot peening is used to replace the residual compressive stresses installed during manufacturer process or cyclic load. With residual compressive stresses. The residual compressive stress’s is what gives manufacture parts, or parts in cyclical load it’s longevity.

Finishing Treatments:

Our team as more then 20 years of industrial experience, peening almost every different type of metal produced today. Our facility is equipped with shot peen machines that can process parts of various shapes and sizes with repeatable and reproductive results.

Additionally: Our mobile crew are equipped with portable machines to perform our shot peen process anywhere in the USA Whether in-house or in the field.

For all your shot peening needs we are here 24X7

The number 1 Shotpeening Service in America!!

For any questions, to schedule a service or to request a quote, fill out the form or give us a call today!

For Pittsburgh and nearby cities call:

(724)-385-0536

For cities outside Pittsburgh call:

(724)-385-0536

The Best at what we do

© 2022 Appaloosa Concepts LLC. All Rights Reserved.